Request a Call Back

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

,

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Built-in Advantages

Concrete Edge Built-in Advantages

Over 15 Years of Experience | Used in Commercial and Residential Sites | Free Consultation

Over 15 Years of ExperienceUsed in Commercial and Residential SitesFree Consultation

Multiple Advantages Come With EnergyEdge Products

EnergyEdge products offer both built-in and built-on advantages. These numerous and adaptable features make our concrete edge forming systems perfect for just about all your foundation and slab-on-grade assembly projects.

Insulating Protection Built Right Into Your Edges

Our basic forming, protecting, and insulating features are essential when you want to achieve a continuous insulation (CI) building envelope and want to meet ICC building and energy codes.

Without edge insulation, exposed concrete edges become highly effective as a conduit for heat loss, as detailed in a DOE research study on slab edge insulation (SEI) conducted by The Davis Energy Group in "Exposed Slab Edges: The Last Big Leak."

Exposed edges lead to heat energy being continuously wicked from the building's interior, leaving cold floors and cold occupants. The most likely remedy is to set the thermostat higher, which leads to higher energy consumption and costs.

Our Built-On Advantages Making Building Easier

When we talk about "built-on" advantages, we're addressing the many construction materials, assemblies, finishes, and weeping systems that terminate and transition at your slab edges. These complexities are made more demanding by the physical and environmental exposure you get with "at-grade" detailing.

(Please note that where manufacturers' or organizations' names or materials are recognizable in these images, EnergyEdge does not claim responsibility for that particular product's performance. We are using them only as an example of how our system interfaces with that type of material.)

Free Consultations

Call for more information!

(316) 618-1983

(316) 618-1983

EnergyEdge is new to our design build team, especially in the context of a 310,000 sq. ft. commercial office building governed by a market-rate construction budget. But we've embraced this idea and see so much value in understanding how to use EnergyEdge to its full potential now and in the future.

- Clint Blew, Senior Design Architect, Burns and McDonnell Engineering

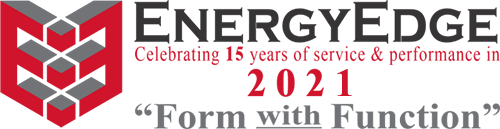

Foundation Type 1.0, Mono Pour and Slab

Summary: These types of foundations are generally used in areas with very shallow or no frost depth. They also tend to be more common in regions with arid weather conditions because footings will remain exposed during ground utility rough-in processes. Below grade and exposed edge insulation provided by EnergyEdge insulated forming rails form the perimeter of this foundation type. EnergyEdge remains in place to protect and insulate the exposed slab edge transition from below grade insulation to the wall insulation on the slab edge. Concrete material for footing and slab edge are poured in one process, hence the term “mono-pour” or “ONE pour."

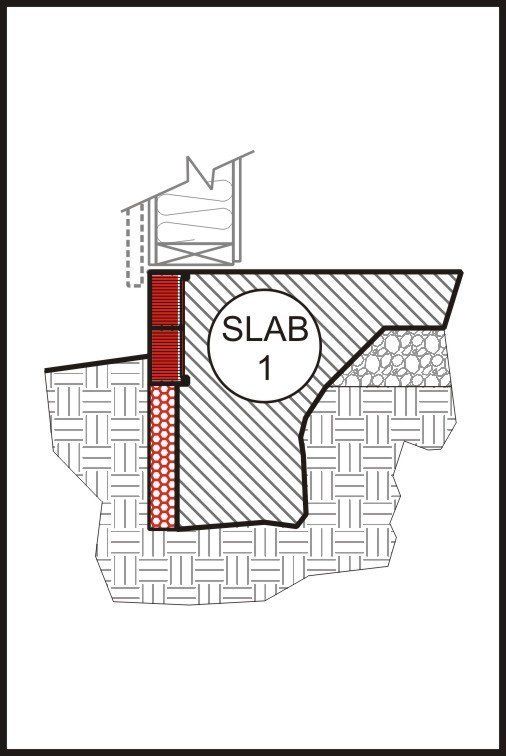

Foundation Type 2.0, Grade Beam and Slab

Summary: These types of foundation are generally more common in climate zones where frost depth is 30” or less but can be used across all climate regions. This assembly employs a simple “grade beam” footing/foundation formed by a simple earth formed trench. Below grade insulation is installed on the exterior of the formed trench and generally aligned with structures slab edge. Slabs edges are formed using EnergyEdge insulated forming rails at a typically thickened 8” edge. EnergyEdge remains in place to protect and insulate the exposed slab edge transition from below grade insulation to the wall insulation on the slab edge. This assembly is generally a “TWO Pour” process,

- Pour “grade beam”

- Pour thickened edge slab.

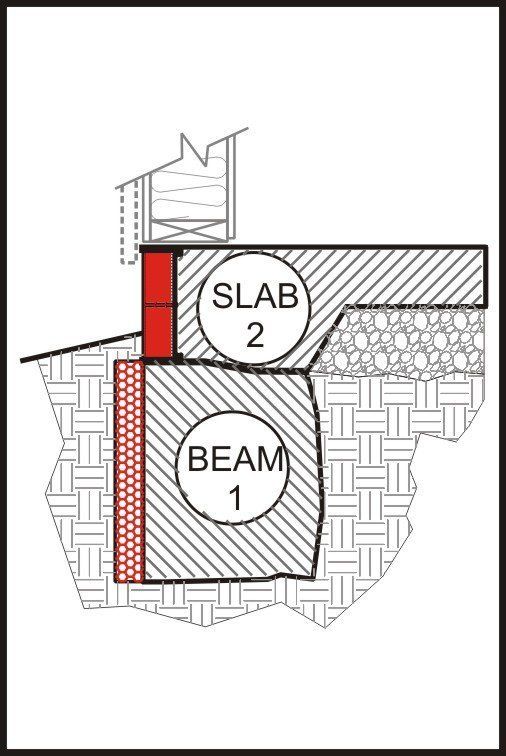

Foundation Type 3.0, Footing, Stemwall, and Slab

Summary: These foundation assemblies are most common. Type 3 foundations and its many variations (Including frostwall foundations) are used across all climate zones. Its engineering, design and construction flexibility deliver precise results. Below grade insulation is easily applied to the outside flat surface of the stemwall with 8” thickened slabs formed using EnergyEdge insulated forming rails. EnergyEdge remains in place to protect and insulate the exposed slab edge transition from below grade insulation to the wall insulation on the slab edge. These “THREE pour” assemblies consist of a footing, a formed stemwall, and then the concrete slab.

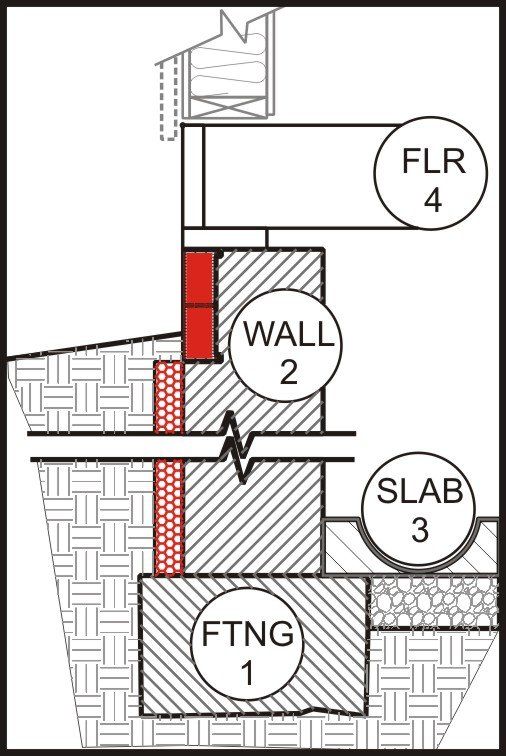

Foundation Type 4.0, Basements, and Crawl Space Foundations

Summary: These types of foundations form below-grade spaces for basements and crawl space areas. They consist of the same three basic formed concrete elements as the Type 3.0 foundation with the addition of a floor assembly across the top. These below grade areas typically require perimeter insulation and include a concrete transition from below grade to sill and joist assembly bearing. EnergyEdge insulated forming rails used as a foam insert at the top exposed edge provide the necessary thermal break from rim insulation material to below grade insulation. EnergyEdge remains in place to protect and insulate the exposed slab edge transition from below grade insulation.

The foundation assemblies above represent a cross-section of generic foundations used by EnergyEdge to qualify and categorize various construction sequences and requirements. There are many variations and hybrids to these systems. We invite you to consult with us regarding how to best provide specific system needs, walls, glazing, and finishing material challenges.

VISIT US

,

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

CONTACT US

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Hi. Do you need any help?

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.

Share On: